Great design, successful product

“Industrial Design (ID) optimizes the function, value and appearance of products, so that customer buy higher value products and manufacturers gain lower production costs.”

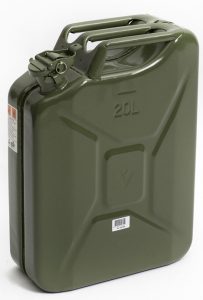

One great example of how industrial design creates hugely successful product is the humble Jerrycan:

During WW2, the allied forces in North Africa transported fuel and water in square boxes, welded along each edge. They nicknamed these boxes “flimsies”, since they usually leaked.

The German “Wehrmachtskanister” was easy to manufacture. It comprised 2 pieces of pressed steel that slotted into each other. Most importantly, they could be welded together in one continuous path. In addition, rounded corners helped ensure these cans didn’t leak. The pressings were also indented on each side to add strength, without creating a stress point. Even the cap was designed for quick release, and remained attached to the can, so it couldn’t get lost. As the cans contained 20 litres, one man could easily carry a can in each hand. Three handles enabled a “bucket brigade” to quickly load or unload a supply truck.

The success of this product was obvious when Allied soldiers rapidly adopted captured Wehrmachtskanisteren, renamed them “Jerrycans”, and soon produced their own versions.

The design of the ‘jerrycan’ did not come about by accident, it evolved through a well defined process which considers; function, materials technology, human factors, economics and engineering all of which form the basis of the modern design process.

As products and markets have changed, Industrial design has evolved into a specialist subject which blends production engineering, materials technology, ergonomics, colour theory, and graphic design. It combines engineering with art; it bridges the chasm between technology and people; it is creative yet utilises a well defined process. The result is added customer value and reduced manufacturing costs.

The Olivetti Valentine typewriter (1969) designed by Ettore Sottsass turned, what was, a utilitarian machine into a must have of the day. It put Olivetti on the map. Using modern materials, new manufacturing process’ and clever design, Olivetti’s portable typewriter created a new mass market product category.

The Industrial Design Process

Great industrial design is 99% perspiration and 1% inspiration (to paraphrase Edison!). It is an understood, structured, and scheduled process comprising the following steps-

- Briefing – during which the industrial designer, marketing, technical, and production people pool their expertise. Often the outcome is a formal written document that lists required and desirable features or attributes. This process aligns the objectives of multiple departments. A brief could include:

- Target user and use-case

- New, innovative technologies the product would exploit

- Projected volumes, retail price-points, and target manufacturing costs

- Research is the step that demands perspiration, but lays the foundations for subsequent steps. Depending on the project, most designers like to fully appreciate the following:

- Users’ requirements and desires;

- Materials and enabling technology;

- Production process;

- Market trends and competitor’s offerings;

- Idea Generation is what designers do best. Using the results of their research they brainstorm, sketch and model, either alone or with the client’s team. The aim is to generate a number of viable solutions for presentation to the team, from which the best are selected for further development.

- Refinement means creating a feasible concept that can be prototyped. Typically, the concept is fleshed out using 3D CAD tools usually in conjunction with other skill sets. Collaboration with other departments is essential and can involve electrical, mechanical and production engineers, as well as product marketing and salespeople. The result is a prototype of a final design, which not only satisfies the criteria in the original brief but can add additional features that provide a competitive edge.

- Documentation of the agreed design enables effective collaboration across production, marketing, distribution and sales. All groups reference a single version of the truth, as they bring the product to market. At a minimum, the documentation should include design intent drawings that detail key design features, materials, and the finish. It contains sufficient information to ensure production can make the product, and sales can sell the product, with the minimum of changes.

Next Steps

Products benefit from industrial design being integrated into the development process, especially at an early stage. Using Industrial Design will help you create products that achieve higher sales, and lower manufacturing costs. You can download a great guide to buying design from the Design Council here.